OVERVIEW OF MATTING AGENT

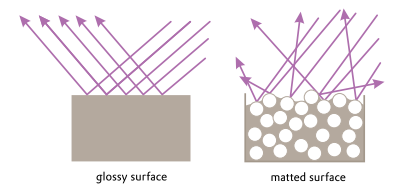

When light is reflected on a smooth and slick surface, the surface becomes glossy. When light hits a rough, uneven surface, instead of reflecting light, it is scattered, creating a matte surface. A variety of natural or synthetic materials that are added to paint films primarily to reduce shine are known as opacifiers.

Photo 1. Reflection of light on glossy (left) and matte (right) surfaces

The matting agents with small medium particle sizes have a low matting effect but give a smooth and smooth paint film surface. In contrast to the larger particle size, the matting efficiency is high, but the paint film surface is less flat and easy to settle during storage of the finished paint.

It is not easy to decide on the best matting agent. This depends on the final application of the coating, as well as on the required dry film properties: clarity, smoothness, corrosion resistance, and weather resistance. In addition, the choice of opacifier can make a significant difference in terms of viscosity, re-dispersion and gloss stability.

Classification of matting agents:

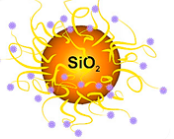

Silica matting agent: there are two main groups due to differences in their manufacture

- The hydrothermal process produces relatively soft silica (fumed silica).

- The product of acidification of the sodium silicate solution is dehydrated, to give a more rigid form of silica (precipitated silica)

- In addition, both types above can be surface modified with wax or inorganic substances to add some properties to the paint such as anti-settling, increased adhesion, scratch resistance, increased opacity, etc.

Photo 2. Silica beads have been surface modified with wax.

Wax opacifiers: based on Polyethylene, polypropylene, polyamide, polytetrafluorethylene, palm leaf wax, etc. Unlike silica opacifiers, wax modifies surface properties by floating on the surface of the paint film.

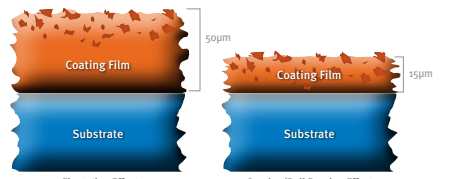

Rely on each type's dimming mechanism to come up with the right usage for each application. For example, paints with high film thickness (or low shrinkage) wax matting agents will be more effective because wax polymers tend to rise to the surface to change the film properties; Paints with low film thickness (or high shrinkage) silica matting agents will be more effective àbecause when the paint evaporates the solvent helps the silica powder to be evenly dispersed throughout the paint film when the paint film thickness decreases due to flying. In the solvent vapor, the silica particles are exposed creating a micro-rough surface.

Photo 3. Application of wax opacifier (left) and silica opacifier (right).

Above is some information about some types of matting agents and paint applications. Hopefully, we could bring you informative information.

>> Nhận tư vấn chuyển giao công nghệ sản xuất sơn chống cháy <<

Mọi thông tin vui lòng liên hệ:

Văn phòng: Tầng 2, A2-IA20, KĐT Nam Thăng Long, đường Phạm Văn Đồng, P. Đông Ngạc, Q. Bắc Từ Liêm, TP. Hà Nội, Việt Nam

Trung tâm nghiên cứu: Thôn Nhuế - xã Kim Chung - huyện Đông Anh - Tp. Hà Nội - Việt Nam.

Website: megaradcenter.com

Tel/Fax: (+84) 24 375 89089 / (+84) 24 375 89098

Email: contact@megavietnam.vn